- Written by Rick Bruno

- Category: Resistance Welding Types

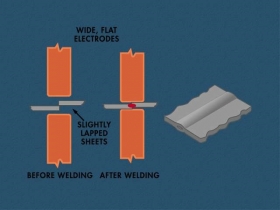

Lap seam welding is a type of resistance welding, also known as electrical resistance welding (ERW). Unlike arc welding, which uses gas, resistance welding uses a strong electric current to join two metal parts. The current heats the metal parts at the welding joint, causing them to melt and forge together. In seam welding specifically, the weld wheels (electrodes) apply the force and deliver the necessary current. After the weld absorbs heat energy from the molten weld joint, a weld nugget forms at the point of solidification. Applying pressure before, during, and after passing the electric current helps maintain the heat at the pressure application point. This process works well on low carbon steels, high alloy steels, stainless steel, aluminum, titanium, and more.

- Written by Rick Bruno

- Category: Resistance Welding Types

You may have heard of resistance welding, but have you heard of resistance brazing? In this article, we explain what this technique is, how it is performed, and what the advantages are in using it.

- Written by Rick Bruno

- Category: Resistance Welding Types

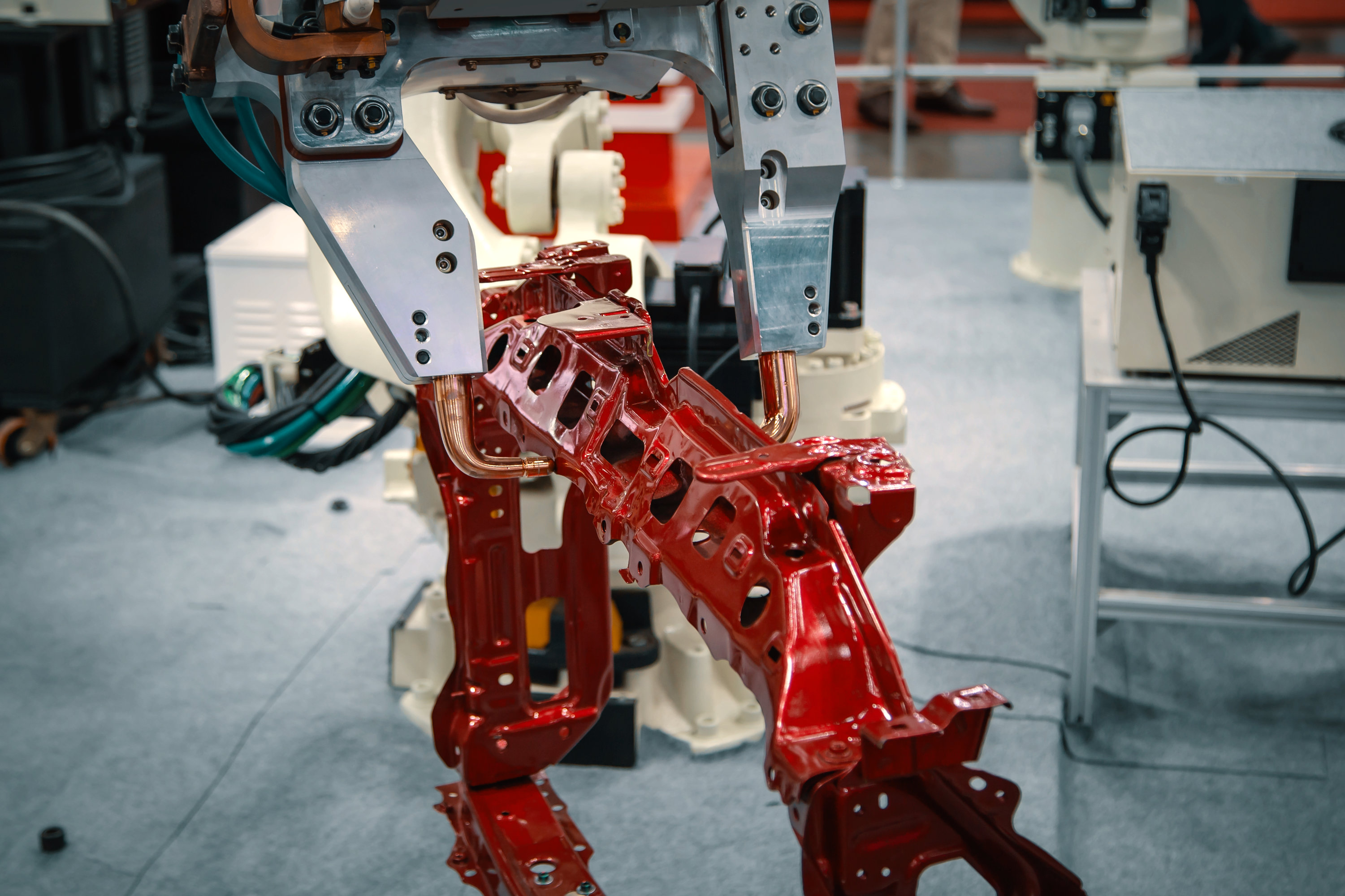

Flash welding is a popular resistance welding technique that involves joining two pieces of metal together using an electric arc. This technique is applicable for users in the metal-making industry.

It has become one of the popular methods for welding steel but also for nickel, aluminum, and titanium alloys. These metals are important for manufacturing sectors such as automotive, aerospace, heavy equipment, and more.

This blog post will go into detail on what flash welding is, the process of doing it, and why it's essential in the manufacturing industry.

- Written by Rick Bruno

- Category: Resistance Welding Types

In all walks of life, using the correct tool for the job is an essential part of making your work easier, more efficient, and more effective. Welding is no exception to this rule, as evidenced by the abundance of forms and techniques involved in the process. While many types of welding appear similar on the surface, they vary widely in the processes they use to achieve fusion and the results they can produce. Today, we’ll talk about MFDC welding, and the potential benefits it provides to companies who choose to implement MFDC welding technology.

- Written by Rick Bruno

- Category: Resistance Welding Types

Resistance welding, while being a subset of welding practices itself, is a fairly broad category. Many different variations of resistance welding are needed to apply the correct forces to the correct places in different situations. One of the most common variations of resistance welding used in manufacturing facilities is projection welding. We thought it might be useful to give some background information on what the process of projection welding entails, how it is used, and why. (Don’t worry, we’ve included pictures.)